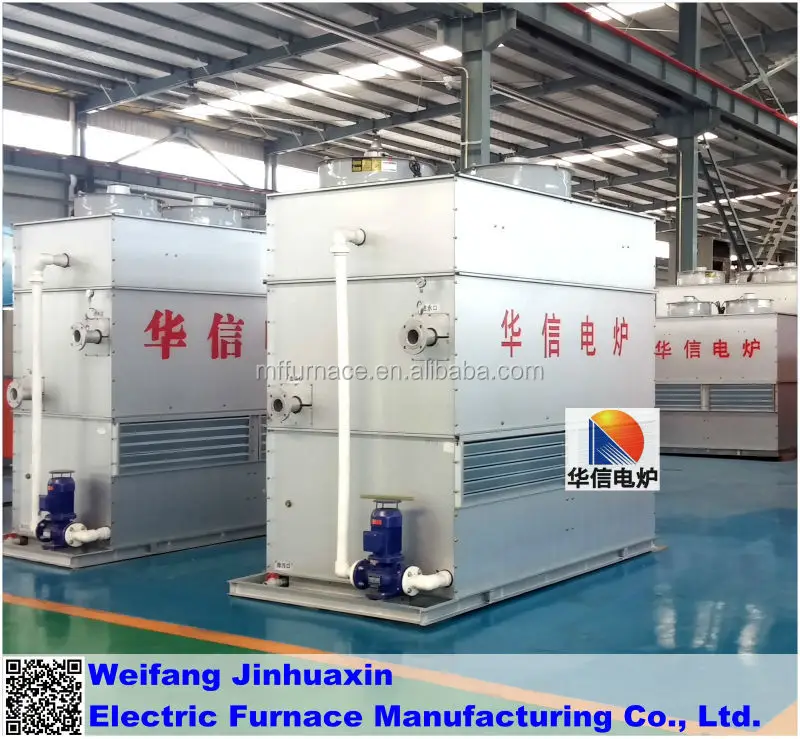

1 HUAXIN WATER COOLING TOWER

Huaxin specialize in the design,research,manufacture and sale of the Water Cooling equipment. Main products: Closed Cooling Water, Transverse Flow Cooling Tower, Countercurrent Tower, Refrigerating Machine and Evaporative Machine etc. Company has the extensive products,we can also provide other relative accessories and technical consultation at the same time.Keeping improving is our constant purpose, every step we can do better from the selection of the raw material to the research and manufacture of a series products.We consider more for our clients.

2 Enclosed cooling tower advantages

1). Fully enclosed circulating cooling, eliminate the pipeline jams caused by debris.

2). Use soft water circulating cooling; no overheat damage of power supply, silicon control, capacitor, IGBT module, induction coil caused by incrustation.

3). No need of water pool and cooling tower, occupies small area, and moves easily.

4). High cooling efficiency and low operate cost.

5). Low water consumption, meet requirement of environment protection.

6). No ionic conduction in soft water, the cooling part will not be broken by the electrolysis.

3 Closed Water Cooling Equipment

1) Main Part:

The main unit of cooling tower consists of housing, purple copper cooler, exhaust system, spray system, water separator, and collecting annulus.

2) Main Part Shell

It is made of stainless steel plate, 2mm thick. Its resistance to corrosion is as well as stainless steel. The housing is pieced together without welding after cutting, folding and

rinsing by numerical control machine. So it looks artistic, and the size is accurate

3 )cooler

The key part of cooling tower. Its inside connects coolant, and the outside is designed to be cooled by the air cooling and water spraying to meet the cooling demand. In order to ensure the cooling effect, cooler is made of T2 purple copper tubes which are in accordance with international standard, and all tubes are bare purple copper tubes without fins (This is our own technique that upgraded according to many years experience. Because aluminum fins are easy to oxidize and corrode, so its useful life is short. Now, we use T2 purple copper tubes which the resistance to corrosion is much better. And the entire outer cooler is made of bare copper tubes, so its corrosion resistance is much stronger). The joint between copper tubes and angle fitting are welded by silver welding rod, so the welding spots become less but the quality is better.

4 ) fan

This system exhausts saturated hot and moist air from main unit room of cooling tower steadily in the airflow way of getting air in through the air intake under the main unit room and getting air out through the upper fan opening. Exhaust system consists of air grid, fan and shield. The fan uses aluminum case, increasing its useful life.

5) Water Separator

The main function of water separator is to reduce the water consumption of outside loop water cooling system in the working process

6 )Auxiliary Machinery

Auxiliary engine, consisting of master pump, stainless steel water tank, electric cabinet, temperature-control system, pressure-control system, etc., mainly performs as control system for cooling tower.

→Standard equipment is a master pump, a spray pump, an auxiliary diesel engine.

→Recycling tank is made of stainless steel sheet and plate 304, and is equipped with liquid level alert system at the inlet. The circulating cooling medium is enclosed while there’s still light deterioration. The liquid level indicator detects and alarm automatically so as to supplement the aqua pure for the internal recycling system.

7) Water Cooling Automatic Control System

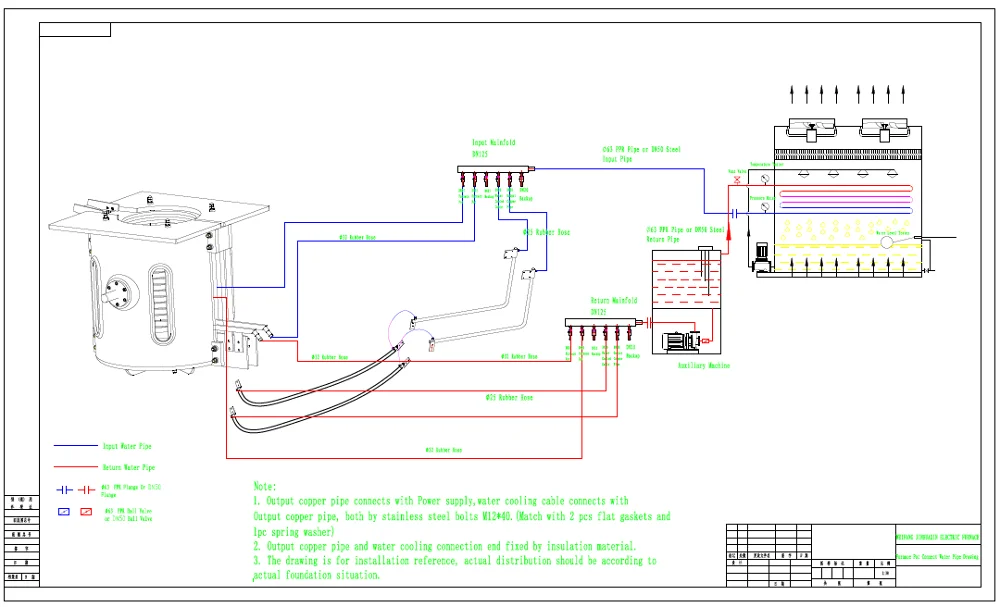

4 Medium Frequency Furnace Cooling Drawing

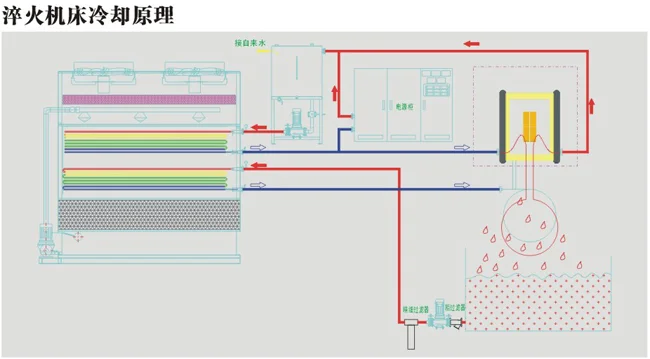

5 Hardening Machine Cooling Drawing

6 Closed Water Cooling Equipment Application Cases

7 Company Introduction

why choose huaxin?

Shandong huaxin Electric Furnace Co., Ltd is a high-tech enterprise which specialize in the research and manufacture of induction heating equipment. Huaxin Electric furnace professionally manufacture products: KGPS series Medium Frequency Power Supply, IGBT series Medium Frequency Power Supply, GTR series Medium Frequency Induction Heating Furnace, GW series Medium Frequency Melting Furnace, Medium Frequency, High Frequency Induction Hardening Furnace, Medium FrequencyHardening and Tempering Production Line(Slack Quench). The equipment widely used in forging, casting, heat treatment, mechanical thermal processing, power metallurgy and other fields.

After its established, we have formed the unique technology advantage in the field of induction heating through cooperation with domestic scientific research institutions and universities. With many years great concentration development, the silicon controlled induction heating equipment of Huaxin Medium Frequency has been equipped the design of the leading level and manufacture ability in domestic.

Over the years, Huaxin adhering to the “Seeking research and development human source and excessive technology” quality policy, in competitive market, continuously create, make progress, surpass and perfect, win more and more friendship, trust, support and respect.

Huaxin always follow the business philosophy of “Science and technology creates value, Integrity casts Brand”, willing to service society better with sophisticated products, become excellent and professional manufacture of Medium Frequency Equipment.

Name: Sunny Chen

Tel: 15621586727