1.Product Name And Technical Specifications

0.05T Intermediate Frequency Aluminum Shell Induction Furnace

|

Model

|

Rated Capacity

|

Rated Power

|

MF Frequency

|

MF Output Voltage

|

Plus

|

Melting Time

|

Electricity Consumption

|

Transformer Capacity Required

|

Water Cooling Consumption

|

|

GW0.15T160KW/1S

|

0.15T

|

200KW

|

1KHZ

|

750V

|

6

|

50min/batch

|

720KWH/T

|

250KVA

|

12T/H

|

2.Furnace Introduction

1).Furnace Parts:

The mechanical parts of the MF furnace consisted of furnace pot,water power introduced into the system, titling device and other parts.

2).Furnace Ports:

Furnace port including furnace shell, induction coil etc.

3).Furnace Shell

Furnace shell made of cast aluminum furnace shell halves connected together, with good rigidity, compact structure, easy maintenance, etc., the rotary bearing hole once processed, to ensure concentricity of the furnace shell and rotary bearing tilting furnace process will not be deformed due to misalignment.

3.Aluminum shell furnace Structure:

(1) Aluminum Shell Furnace body use thicken aluminum alloy shell, reduce magnetic leakage and ensure furnace body strength;

(2) Thicken wall induction coil use T2 standard copper tube, offer larger melting capacity, improve electricity efficiency by turn-to-turn space of induction coils;

(3) Open type furnace hearth reduce moisture, and design cooling rings on bottom, which extend brasque lifetime;

(4) Use entire fireproofing tile to replace asbestos rings, reduce furnace body using cost greatly.

4.Induction Coil Design Principle:

Coil is the heart of induction furnace, induction coils will produce a strong magnet field under the action of the electric current. Coil design is very important since Coil is the key part of the conversion betweenElectrical energy and heat. 99.99% red copper.

5.Reducer Features and Applications:

Reducer mainly by the transmission parts (gears or worm), shafts, bearings, housing and accessories formed. Is divided into two kinds of manual and electric, our company is the use of electric reducer.

Applied to the furnace shell furnace tilting, and compared to traditional manual gearbox, more secure and reliable, the speed proportioned.

6.Tilting Control Box:

Tilting control box is in front of the furnace body, used to control the tilting (in the range of 0 ~ 95 degrees). It uses gear and steering operation, reliable, smooth, non-impact and creeping phenomenon, can stay in any position.

7.capacitor

The device has a capacitive load with inductive load and coupled to the same circuit,when the capacitor load release energy,the inductive load absorb the energy;While inductive load release energy,the capacitor absorb the energy.Energy is exchanged between the two load.Thus, the inductive load reactive power absorbed by the capacitive load of the output of the reactive power compensation,This is his compensation principle.

8.Crucible Model:

3mm thick iron plate perforated by the bending of welded for lining knotted mold, mold is used to control the crucible refractory lining (crucible) the shape and volume of the mold. According cast metal material and sintering methods, the use of crucible materials and forms are not the same mold. To be used when firing from sheet or thin iron processing welding crucible made of die

9.MF power supply

The three-phase frequency AC power supply through the three-phase bridge rectifier becomes adjustable DC power supply, and then filtered through filter choke input to a single phase inverter bridge, the pulse control, the single-phase bridge diagonal alternately switches become a single with 1000 Hz frequency current, vibration route composed of the induction coil and the compensation capacitors

Sent current into induction coil, and make the intermediate frequency eddy current sensor in the metal furnace charge, charge with the heating and melting.

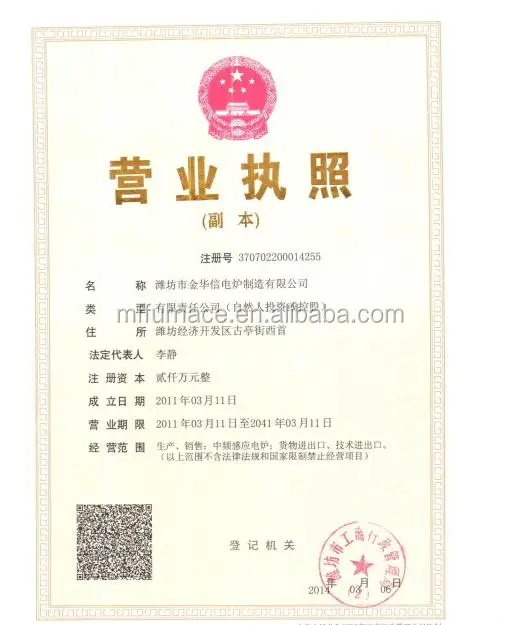

10.Compony Introduction

Huaxin always follow the business philosophy of “Science and technology creates value, Integrity casts Brand”, willing to service society better with sophisticated products, become excellent and professional manufacture of Medium Frequency Equipment. With good quality and competitive price.

Shandong Huaxin Electric Furnace Co.,Ltd is a high-tech enterprise which specialize in the research and manufacture of induction heating Huaxin Electric furnace professionally manufacture products:KGPS series Medium Frequency Power Supply, IGBT series Medium Frequency Power Supply, GTR series Medium Frequency Induction Heating Furnace, GW seriesMedium Frequency Melting Furnace, Medium Frequency, High Frequency Induction Hardening Furnace, Medium FrequencyHardening and Tempering Production Line(Slack Quench). The equipment widely used in forging, casting, heat treatment, mechanical thermal processing, power metallurgy and other fields.

After its established, we have formed the unique technology advantage in the field of induction heating through cooperation with domestic scientific research institutions and universities.With many years great concentration development, the silicon controlled induction heating equipment of Huaxin Medium Frequency has been equipped the design of the leading level and manufacture ability in domestic.

Over the years, Huaxin adhering to the “Seeking research and development human source and excessive technology” quality policy, in competitive market, continuously create, make progress, surpass and perfect, win more and more friendship, trust, support and respect.

Huaxin always follow the business philosophy of “Science and technology creates value, Integrity casts Brand”, willing to service society better with sophisticated products, become excellent and professional manufacture of Medium Frequency Equipment.

If you are interested in our products, please contact us through the following ways:

Name:Sunny Chen

Email:sunny@jhxjd.com

Tel & Whatsapp: 15621586727